When selecting a hose assembly, be certain it meets:

- Size requirements

- Pressure requirements, both operating and profile or application

- Temperature range

- Fluid compatibility

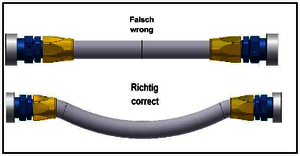

All hose assemblies whether rubber or PTFE, should always be handled with care to prevent excessive bending, twisting and kinking. Dragging hose on ground surfaces, using them as climbing handles and severe bending to fit cramped storage areas must be avoided. Kinking of hose occurs more easily in larger sizes and in very short assemblies. Care should be exercised in handling and installing both rubber and PTFE hose assemblies.

Proper Installation

- Attach the hose to the most inaccessible end of its routing first. Finger tighten only, so the hose is free to turn during initial installation. Hose should not be twisted on final installation.

- Attach the other end of the hose in the same manner.

- Properly orient the hose along its routing and install the required line support clamps.

- Use proper torque and remember to always lubricate! Use established installation torque values or consult ARP908 for limits. Also, the Flats From Finger Tight (F.F.F.T.) method is simple to use and more consistent than measuring input force. Dissimilar materials or metals require different values (e.g. aluminium to stainless steel).

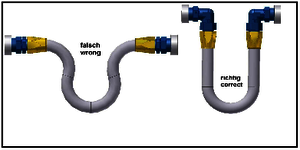

When securing the line support clamps, exercise care in distributing hose slack between the hose connections and the clamps. Do not bend or force the hose to a sharp angle at any location. Be sure to use gradual curves for all routing. Installation of clamps must never restrict travel or cause the hose line to be subjected to tension, torsion, compression, or shear stress during flexing cycles. Avoid installation of undersized hose support clamps. See AIR1569.

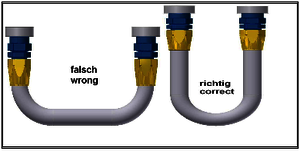

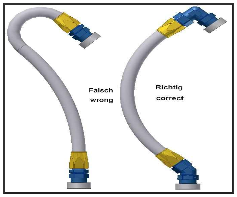

Position hose assemblies so the flexible portion of the hose extends at least one times the hose diameter before starting a bend.ch to hold the nipple hex, if provided, while the other wrench is used to tighten the swivel nut. On hose assemblies that do not provide a hex for holding, use extra care to prevent twisting of hoses.

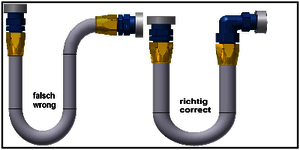

Always lubricate fitting threads prior to installation. Two wrenches may be used to tighten end connections to prevent twisting of the hose or over-torquing of fittings. Use one wrench to hold the nipple hex, if provided, while the other wrench is used to tighten the swivel nut. On hose assemblies that do not provide a hex for holding, use extra care to prevent twisting of hoses.