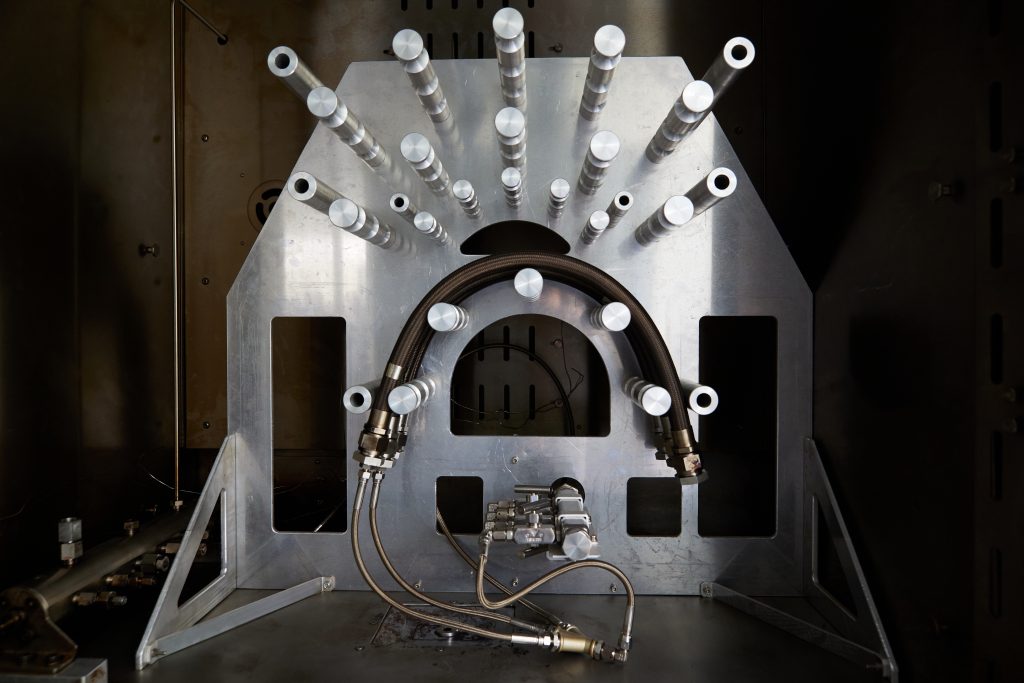

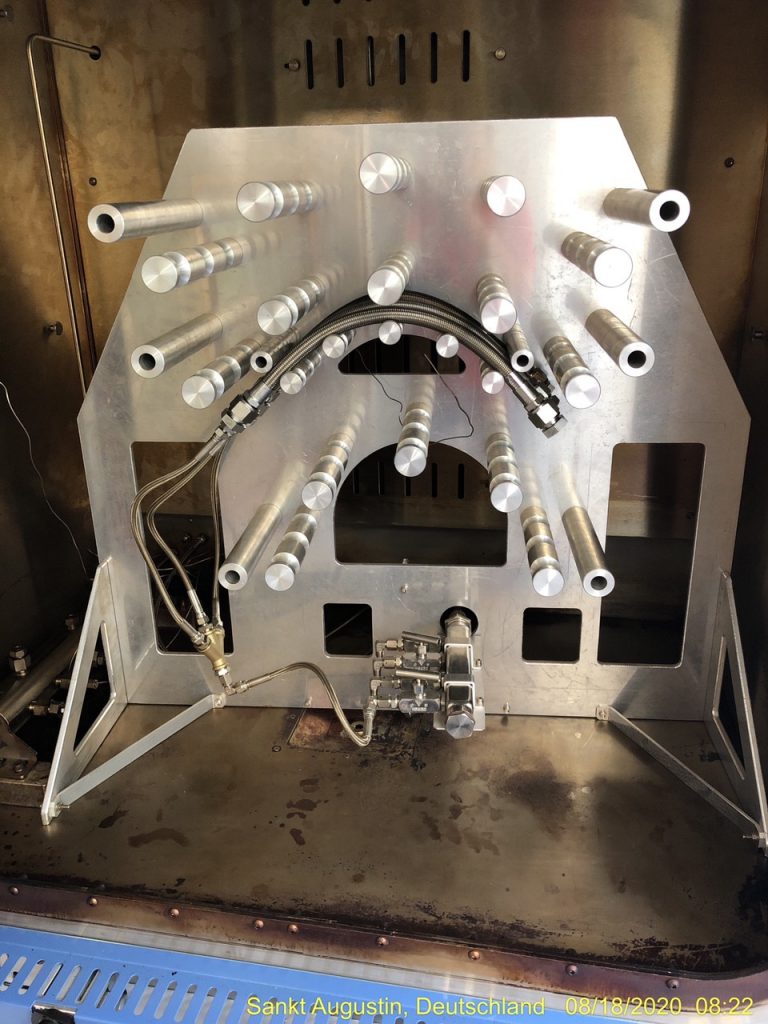

Vacuum test

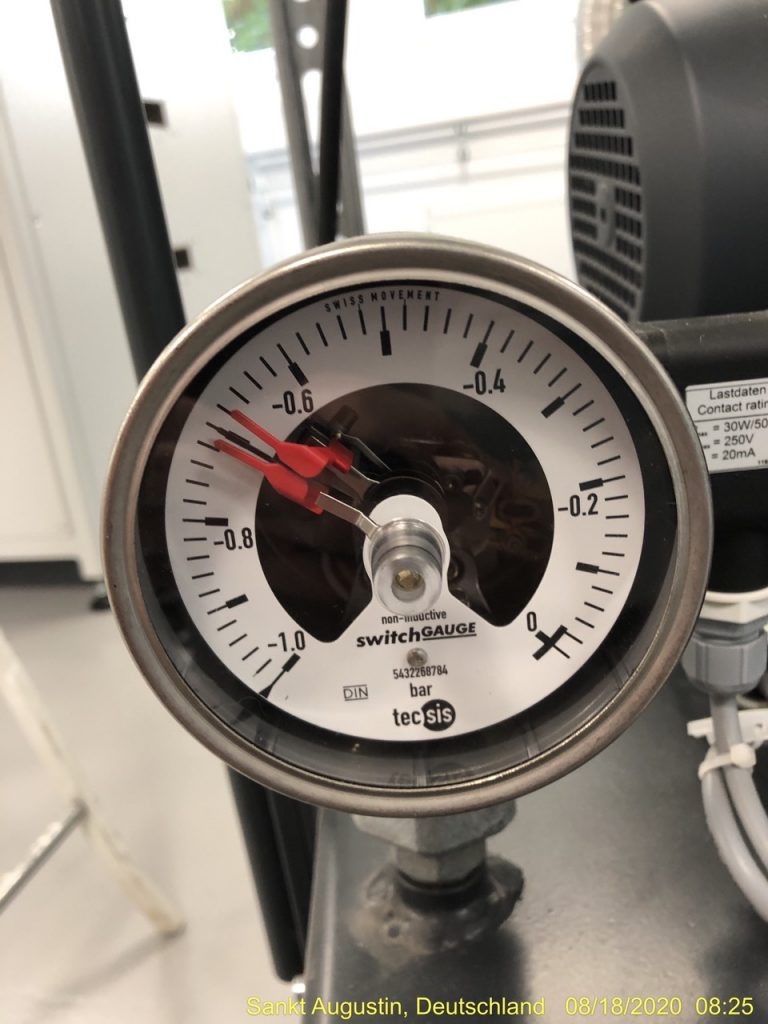

The test aims to verify assemblies for uses where negative pressure can occur.

The hose assemblies are subject to negative pressure for 4 hours at an ambient temperature of 232°C (450 °F).

Afterwards the hose assembly is cooled and the depressurized. The hose is inspected for cracks and defects.