Measuring

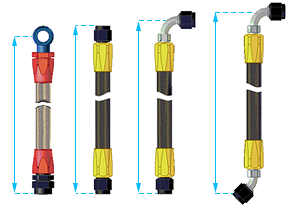

The total length of a hose assembly is measured along the hose centreline from end of nipple to end of nipple. Except of the elbowed fittings and banjos. These are measured – like you can see in the right picture – through the middle of the fitting.

Twist angle measuring

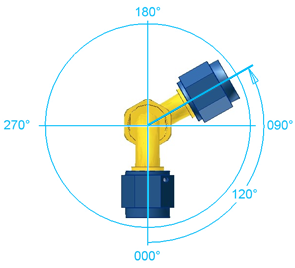

How to measure and specify double elbow fittings on a hose assembly – when installations require hose assemblies with elbow fittings on both ends, hold the assembly so the nearest fitting is pointed in the 6 o’clock position. Measure the angle between the fittings counter-clockwise. When both fittings point to 6 o’clock, this is specified as zero degrees.

Ordering

Usually the best way to get new hose assemblies is to work according to samples. You send us the hose assemblies and we are measuring them ourselves. The advantage is obvious. Experts are taking the characteristics of the hose assembly for example the material (rubber or PTFE), the pressure rate, the application, the type of fitting or the assembly length. You can be sure to get the same type of hose like you had before.

You can also order by the use of the old assembly number. Most hose assemblies are described with a small identification tag. With the help of our database we are able to identify the most numbering systems and to cross reference to Stratoflex. The past showed that most people get used to that way of ordering very fast. Once done it correctly, you save time and expenses every time you are going to order.

If you need to order fast, you can also fill-out our ordering form and send it per E-mail. If you need any help, please contact us.