Why make periodic inspections?

Most aircraft do have system redundancy in the primary systems. This redundancy is made for the case that a system is not working properly or fails completely. In this case a safe operation would still be possible.

The ignition system of small aircraft with piston engines is essential for a safe operation. Therefor the system is redundant, two magnetos are attached to each engine. Only exception are motor gliders with only one magneto. They are called single ignition systems.

Periodic maintenance reduces the possibility of ignition failure.

Good reasons for a regular inspection interval

Motor glieders

If a failure of the ignition system should occur while flying, the engine will stop to fire. You will be able to glide quite a while without it. The stoppage of the engine should nevertheless be seen as critical. Depending on your aircraft you will have more or less minutes left in the air. Shouldn´t you be able to find a good landing possibility nearby within this time range, a crash-landing will be the result. Motor gliders are depending on their single ignition system. Take care of it!

With increasing height, the air density and the insulating resistance are decreasing. The ignition spark can jump uncontrolled within the distributor block. To counter this effect, the magnetos are pressurized. This means that air from the turbo is used for the magneto.

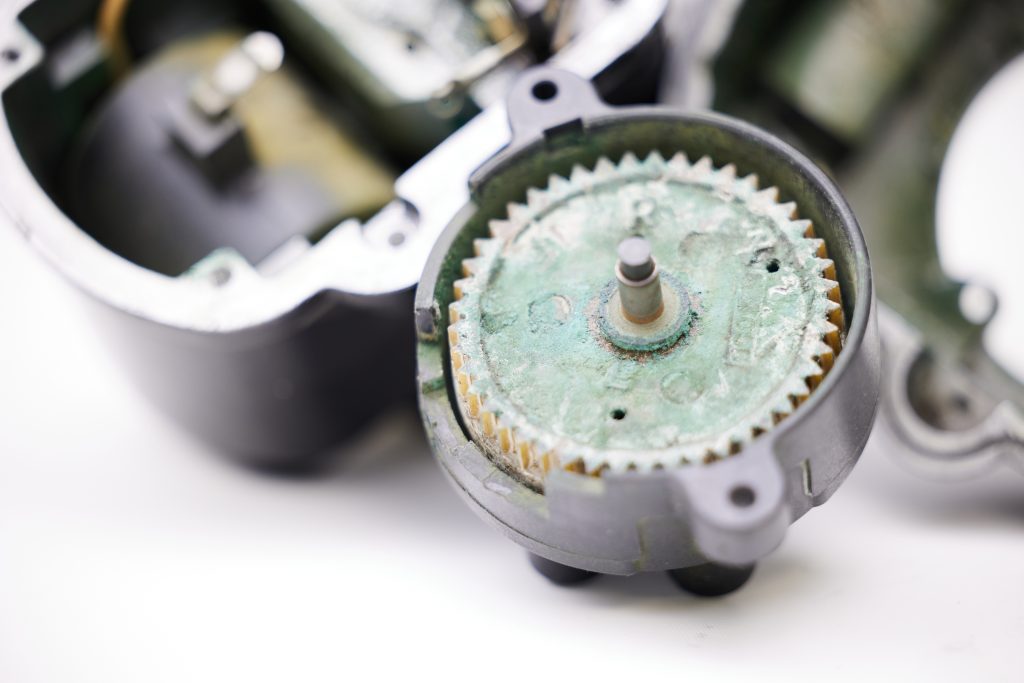

The small hole in the magneto housing which is regularly 2mm, is reduced to 0,6mm in pressurized magnetos in order to keep the pressure. If this small hole is closed (because of dirt), air and ozone cannot get out of the magneto.

Ozone is a very aggressive molecule. It’s corrosive! Plastic material can get weak, metal corrodes and the contact points can have excessive wearing until they stop to open. At this point – at last –the magneto fails. If you plan to make long distance flights with pressurized magnetos check their timing. If you have to time the magneto towards the engine quite often or too much, it could be caused by a worn contact point.

For pressurized magnetos it is important to check this hole at the 50h inspection. Check if it is not blocked – check if air comes out!

Should you notice that there is no air we recommend that you inspect the magneto internally.

Ozone

What does an inspection at WMT include?

All current Service Bulletins (SB’s) and Airworthiness Directives (AD’s) are checked and carried out.

- New shaft seals in order to prevent leakages

- New gaskets are delivered

- For motors and impulse couplers anti seize is used, in order to avoid fretting corrosion

- New bearings for Type S1200 und D3000

- Only original Bendix lubricants are used

- Old oil in the distribution cam is washed via ultrasound. The distributor bar and sockets from the distributor cap are backed at 100°C for an hour with special oil

- Capacitor: the capacity is measured and the load is tested with a condensation tester.

- Black distributor caps are coated with moisture repellent film.

Tip: before mounting rub the magneto plate with some silicone

- Strips and ring are renewed, felt ring is oiled, distributor cap socket is de-oiled, cleaned with ultrasound and oiled again in the oven.

- Distributor finger is cleaned and inspected

- Distributor block is cleaned with ultrasound, cleaned from conductive carbon dust and inspected for fine cracks with a special magnifier glass.

- Every magneto is tested with different speeds on our test bench and the work is controlled by our certifying staff.

- Cores are cleaned and in case necessary lacquered

- Spark coil: resistance is measured, a high tension test is performed and the coil is inspected for small cracks.